Once a good lift arrived at the workplace, the most important process is the installation. Below is the Installation Considerations for Quentin goods lift. Hope you would find this article helpful.

1 Surface Mount

1 Surface Mount

1.1

Floor anchors should be suitable for the floor condition and thickness and meet the manufacturer’s requirements for pull strength.

1.2

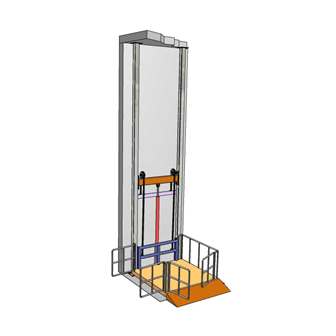

If loading is by other than a counter-balanced fork lift truck, conveyor or by hand, then a ramp may be necessary. Typically there are two types of ramps; a fixed ramp mounted to the floor on the loading side of the platform or a hinge mounted to the platform. If a hinged ramp is considered then the following should be given some thought.

The ramp will have to be raised and lowered for loading.

An electrical interlock should be used on the ramp to ensure that it is in the raised position before operating the goods lift.

If traveling through a hole at the upper level, it may have to be larger to accommodate the ramp, and it may interfere with loading at the upper level. Note: The rule of thumb for length of the incline is 12’’ of length for each 1’’ of rise.

For fork truck loading a curb on the landing should be considered for the loading side in order to protect the goods lift platform from damage by the fork truck.

2 Pit Mount

2 Pit Mount

2.1

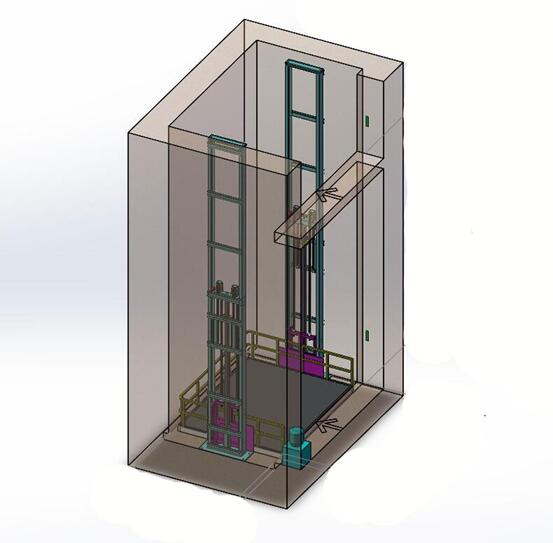

Goods lift may be pit mounted with the entire structure including the mast or

guide beams and the platform in the pit. However, straddle and four post designs allow pit mounting of the platform only with the mast or guide beams mounted to the floor surface and only the platform in the pit in the lowered position. The advantage of this style is the thickness of the floor will carry the load and will normally not require additional footings. Consult your architect before making this assumption.

2.2

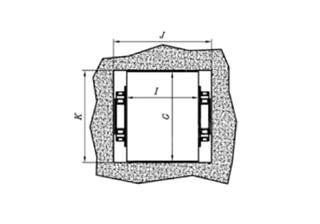

If the entire unit including the mast and platform will reside in the pit, the pit should be sized to accept those components with adequate clearances provided. The manufacturer will normally supply a recommended pit drawing. A normal platform running clearance on the loading side(s) would be 1" maximum and ½’’ minimum.

2.3

The pit floor should have proper drainage and sufficient strength.

2.4

The pit depth should be such that it will allow shimming of the goods lift to bring the platform top surface flush with the floor.

3 Mast or Guide Beam Support

3.1

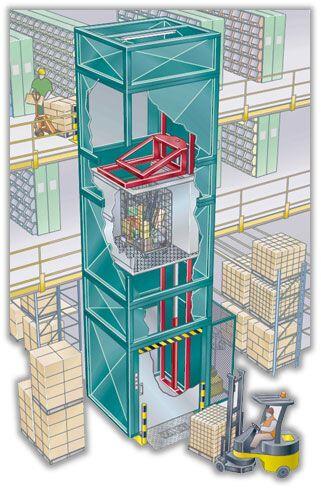

Most cantilever type goods lifts will require the masts to be tied in to the building structure at the upper level and/or at intermediate levels to prevent platform sway caused by the reaction forces of loading and unloading operations at the upper levels.

3.2

Some double mast and four post configurations may be designed to be completely free standing and may not require external support. Most goods lifts require some support or stabilization from the building structure; the goods lift manufacturer will provide the requirements for their particular goods lift model. Note: In some areas seismic calculations may also be required prior to the installation of a goods lift. Check your local and state requirements for criteria regarding the extent of these calculations and the qualifications required by the engineer who performs them.

4

Floor Opening and Mezzanines Floor hole sizes and edge of mezzanine clearance should be per manufacturer’s recommendations.

Where it is not possible to maintain the manufacturer’s recommended clearances a throw-over plate may need to be added to the edge of the goods lift platform or if possible, build out the edge of the landing to ensure safe loading and unloading. If large openings exist it may be necessary to provide additional guarding for personnel safety.

Dealer or Architect?

We will help you provide the best material-handling solution for your next customer or project.

Contact Us:

inquiry@quentin-lift.com

0086-531-88029300